Barcode milling file scanning

For quick and error-free finding of the milled file using the barcode scan.

pedcad knows from its own over 30 years of experience the difficulties and challenges that orthopedic (shoe) technology companies have to face.

Therefore, our developments and research always go in the direction of a simplified and improved way of working.

The barcode milling file solution gives you the option of converting all milling files into barcodes for WIN-based CNC milling machines.

Simply by scanning the barcodes, the wrong milling file can no longer be selected. In addition, the time required is reduced many times over.

Advantages of barcode scanning:

- Fewer rejects

- Less time required to select a milling file

- No trained personnel required to operate the milling machine

- Advanced technology for further developments

This is how it works

1.

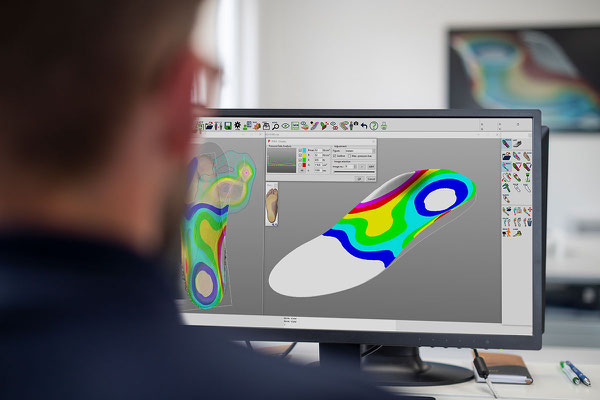

CAD correction

With the help of our InsoleDesigner software, you can open the scan of your patient and make final corrections if necessary.

2.

Create barcode

After you have digitally completed the insert in the InsoleDesigner, you can use it to create the associated barcode on the order slip / batch report and print it out.

3.

Equip milling machine

As usual, you equip your milling machine with the required material for your patient's insert.

4.

Start the milling process

You can now start the milling process by simply scanning the respective barcode. Long searches for the correct milling file or scrap by selecting the wrong milling file are a thing of the past.