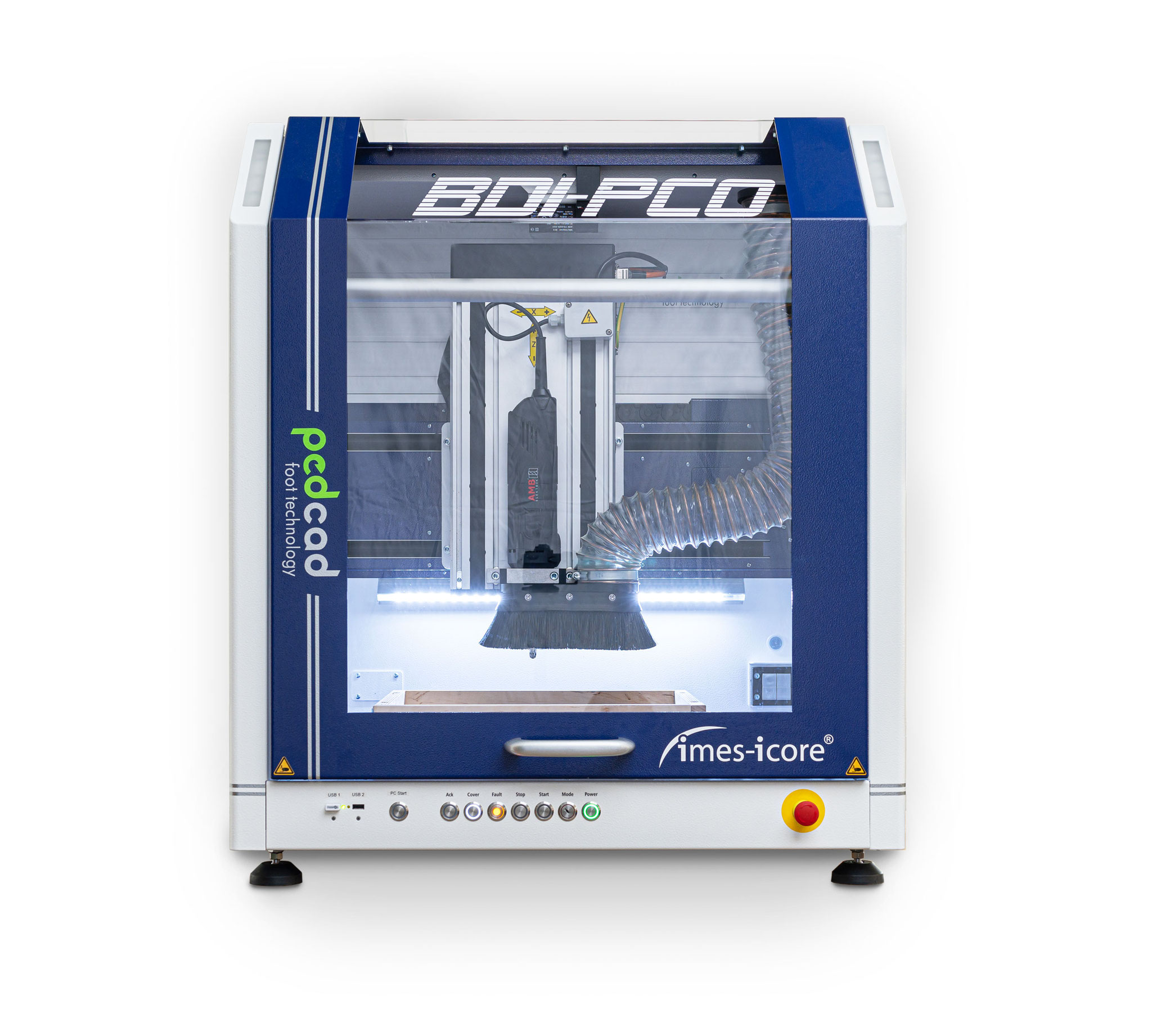

BDI-PCO / BSI-PCO

Our Classics

With our milling machines BDI-PCO and BSI-PCO you get proven milling machines with expandable technology. The two machines differ in their performance due to the built-in motors, the control system used and the processing time per pair of insoles that depends on this. Our barcode scanning and box milling solutions can be retrofitted.

There is no obligation to purchase our milling materials, when purchasing a complete system.

Demonstration models or used machines are available frequently.

Ask us for our current offers!

Get advice now

Advantages

- almost all kind of insoles and type of material can be milled

- delivery is effected with computer and 19" screen

- more effective than conventional insole manufacturing

More technical data

BDI-PCO

Milling machines with Microstep-motors

Processing time per couple:

Ø 30 Minutes

BSI-PCO

Milling machines with Microstep-motors

Processing time per couple:

Ø 12 Minutes

-

Characteristics:

- 3-axis CNC milling machine

- milling in pairs

- insole size up to 50

- insole fixation by box solution

- large operating range

- material thickness up to 60 mm

- installation on site possible

-

Optional features for BDI and BSI:

- Industrial vacuum cleaner

- Mobile base cabinet

- Vacuum solution

- Barcode scanning

- Box solution

-

Scope of supply:

- Control PC

- 19" TFT Monitor

Technical Data:

AC - 230 V, 50/60 Hz

Microstep motors (BDI-PCO)

Servo motors (BSI-PCO)

Dimensions:

769 x 836 x 901 mm

Weight:

approx. 150 kg.

Milling:

Milling in pairs:

Yes / up to 60 mm material

Shoe size:

20 - 50

Milling of top and underside:

Yes

Insole fixing:

Stenter frame or double-sided adhesive tape

Automatic loading and unloading station:

not possible

Processing time:

(varies depending on the milling spacing distance and shoe size)

BDI-PCO

Top side:

ø 30 min./pair

Underside:

ø 6 min./pair

BSI-PCO

Top side:

ø 12 min./pair

Underside:

ø 3 min./pair

Material:

Thickness:

60 mm

Materials:

Single-layer material

Multi-layer material

Inlay blanks

Number of Boxes:

1 Box

Our partner for CNC based milling machines - imes-icore GmbH