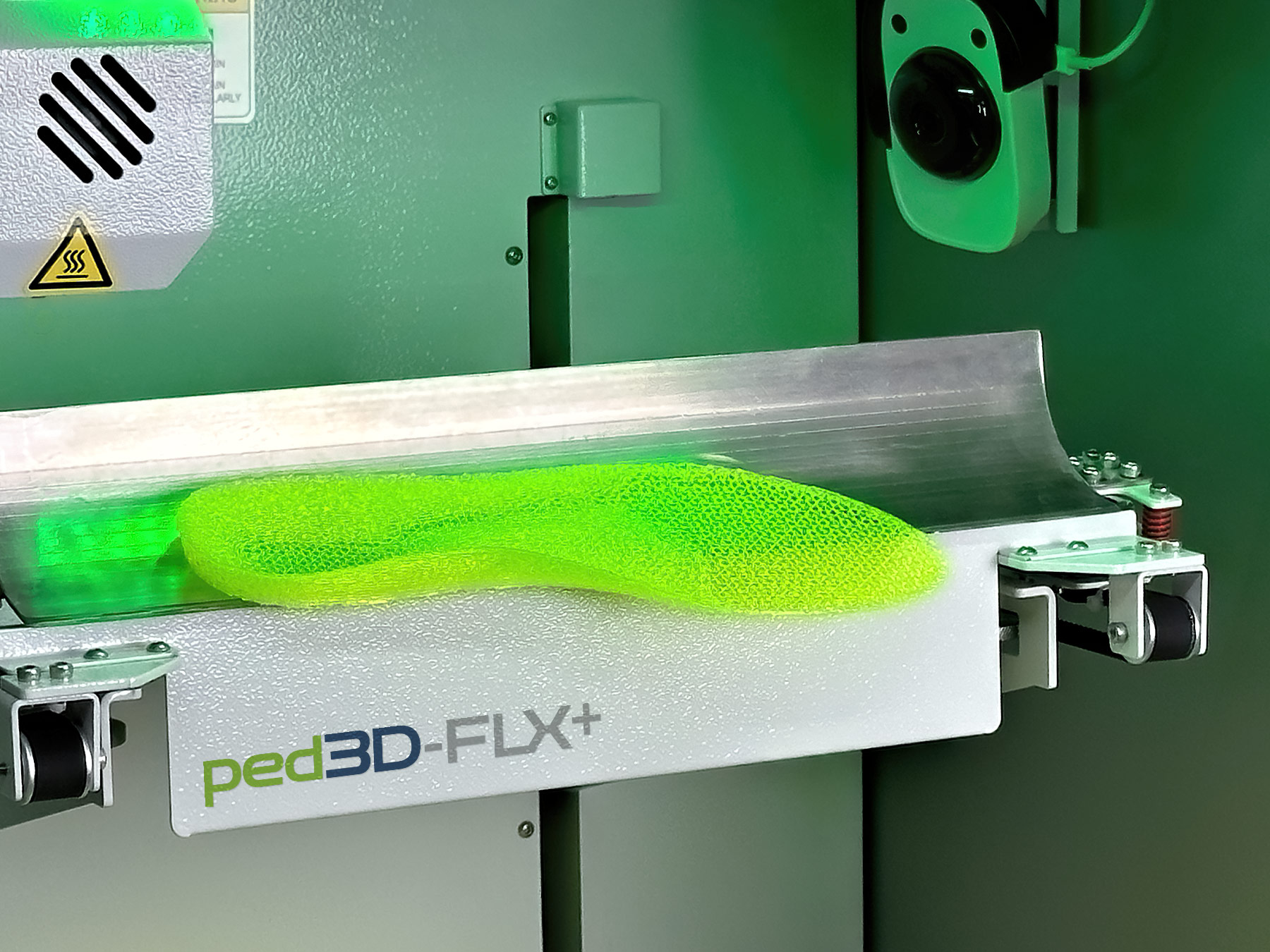

The ped3D-FLX+

Customised insoles in automated series production

Insole production now also automated and in series printing – with the ped3D-FLX+ 3D printer.

Automatically print multiple customised insole orders up to size 48 without continually having to remove the finished product and send a new order to your printer. Simply send your printing orders to the ped3D-FLX+, and then just take care of your day-to-day business. The ped3D-FLX+ completes your orders one by one – completely automatically.

Maximum efficiency in insole production

Thanks to its space-saving design, the ped3D-FLX+ can also be operated almost anywhere, despite its serial printing ability. It is particularly suitable for companies that frequently process multiple insole orders each day and want to provide their patients with the fastest possible care.

High quality and sustainable

Thanks to the innovative 3D printing of our ped3D printer series, you can reduce your waste by up to 95% compared to conventional production methods.

High-precision 3D printing also completely eliminates the need for re working the finished insoles. Most importantly, all our3D printers save you time and additional specialised personnel.

request consultation

Customised serial printing

Best possible efficiency: The ped3D-FLX+ systematically processes a large number of print orders fully automatically.

Independent production location: You do not need a printer cable or LAN connection. The ped3D-FLX+ processes your print orders wirelessly.

Maximum flexibility: You can add print orders at any time. The ped3D-FLX+ will complete each additional order quickly and reliably and store the produced insoles securely in thedevice.

Full control, maximum precision

The high-quality housing and precisely manufactured components of the ped3D-FLX+ provide the 3D printer with maximum stability and precision specialised for series production.

In addition, we offer you various certified and very high-quality materials for the production of insoles. All of the products we offer have been extensively tested, subjected to countless stress tests and are certified. Further information on pedFLX filament can be found in the ⇢ Materials section

Touchscreen control

Everything at a glance: All important information on the status of your current print order and the settings of the ped3D-FLX+ are clearly displayed on the modern touchscreen.

Compatible slicer programmes:

Cura (freeware) oder simplify3D

All 3D printers in comparison

ped3D-solebox

Probably the most uncomplicated 3D printer for fast and efficient insole production.

Specifications:

- Single printing

- Print job starts automatically when the print area is free

- Automatic data transmission without the need for intervention

- Automatic levelling of the print bed

- Printing surveillance via integrated webcam

- Webservice for organization of print jobs

- Internet connection via integrated phone card

- Remote support via webservice

- Device status indicated by light-signals

- Usable only in combination with pedcad insole-design service

- Machine status visible due to light signal and webservice

Financial aspects:

- Low initial invest due to leasing-model

- Material flat rate will be charged with the insole order

- Immediate profit due to low monthly rate

- Service contract grants exchange device in case of irreparable break-downs

ped3D-solebox

ped3D-FLX+

Produce insols in series.

Suitable for companies that frequently process several inlay orders per day.

Technical aspects:

- 24/7 serial printing

- Print jobs are automatically completed one after the other

- Data transfer via tablet

- Semi automatic levelling of print bed

- Printing surveillance via integrated webcam

- App for organization of print jobs

- Internet connection via integrated web cam

- Support only via phone

- Can also be integrated in own design-Software

Financial aspects:

- Complete purchase of printer

- Materials to be purchased in advance for own stock

- Fast ammortization due to low material- and operating costs

- Service contract grants exchange device in case of irreparable break-downs

ped3D-FLX+

ped3D-FLX2

Clean, fast and quiet.

Produce insoles in just 30-60 minutes.

Technical aspects:

- Pairwise printing

- Print job selected and started manually

- Data transfer via USB stick

- Manual leveling of the print bed

- Printing process visible due to glass elements

- Print jobs on USB stick

- No internet connection

- Support only via phone, no status transmission

- No device status

- Can also be integrated in own design software

- Acoustic signal when out of filament

Financial aspects:

- Complete purchase of printer

- Materials to be purchased in advance for own stock

- Fast ammortization due to low material- and operating costs

- Service contract grants exchange device in case of irreparable break-downs

ped3D-FLX2